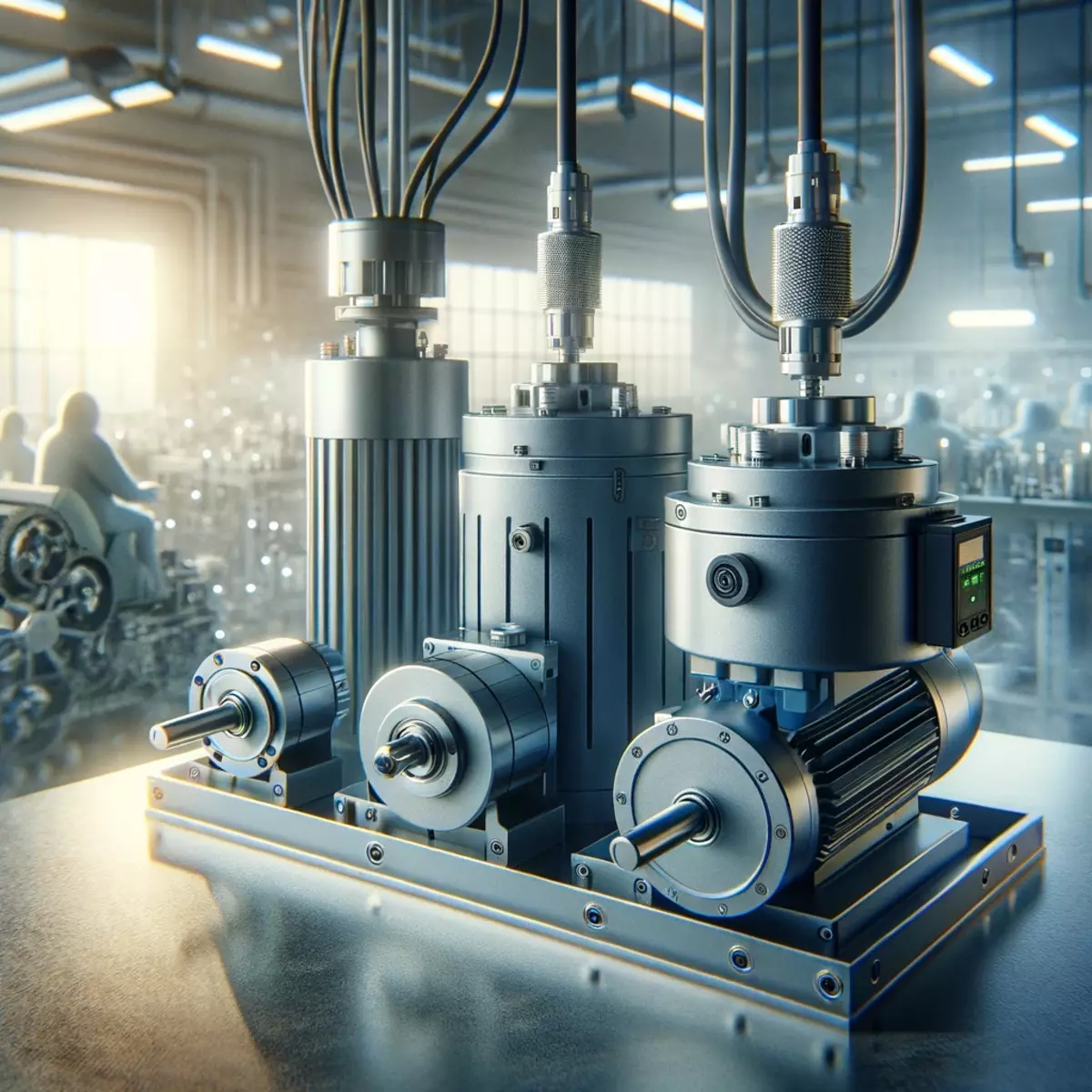

Drive technology for feeders - optimum dosing results thanks to perfect coordination

Feeders play a crucial role in many branches of industry, including the chemical, pharmaceutical, food and beverage industries. They enable the precise feeding of liquids, powders or granulates into production processes. At the heart of these systems are the drive technology and the associated control system, the selection and design of which play a key role in determining the efficiency, precision and reliability of the dosing process.

Drive technologies in feeders range from electric and pneumatic to hydraulic. Each technology offers specific advantages, depending on the application, such as precision when dosing very small quantities or the power to transport highly viscous media. The control of these drives, whether manual, semi-automatic or fully automatic, is crucial for the integration of the dosing device into production processes. It must not only work precisely and reliably, but also be flexible enough to adapt quickly to different process requirements.

The challenge in the development of feeders lies in coordinating the drive technology and control system in such a way that optimum performance is achieved. This requires a deep understanding of both the mechanical and software aspects. The right combination of drive and control technology makes it possible to carry out dosing processes efficiently, precisely and with high repeat accuracy, which is essential in modern production.

What does drive technology mean?

Drive technology refers to the methods and devices used to move or control a machine or one of its parts. In dispensing equipment technology, it includes the systems and components necessary to feed materials in a precise and controlled manner. This can include electric motors, pneumatic systems or hydraulic pumps. The choice of drive system depends on several factors, including the type of material to be dispensed, the required precision and the environmental conditions. Electric drives, for example, offer excellent controllability for small to medium flow rates, while pneumatic or hydraulic systems are often used for larger volumes or for materials that require higher pressure.

The role of drive technology in loss-in-weight feeders

Drive technology is critical to the functionality of dispensing equipment as it forms the basis for the precision and repeatability of dispensing processes. An effective drive system allows exact quantities of materials to be fed at a controlled rate, which is essential to ensure the consistency and quality of the end products. In the pharmaceutical industry, where precise dosing can be vital, or in food production, where adherence to recipes is critical, the precision of drive technology plays a paramount role. In addition, drive technology influences the efficiency of the entire system by optimizing energy consumption and minimizing maintenance requirements.

Difference between drive and control technology

Although drive and control technology are closely linked, they serve different purposes in dispensing devices. Drive technology is primarily responsible for the mechanical movement, i.e. the actual activation and movement of the components that dispense the materials. Control technology, on the other hand, comprises the electronic or software-based systems that regulate and coordinate these movements. It ensures that the drive is activated at the right time, in the right quantity and in the right place. Control systems can range from simple manual adjustments to highly complex, fully automated interfaces that are able to adapt and optimize themselves based on feedback from the production processes. This differentiation is crucial to ensure efficient and precise dosing processes in industrial applications.

Elektrische Antriebe

These are characterized by precision, energy efficiency and simple controllability. Ideal for high-precision dosing, they enable clean and quiet operation. Specific:

- Stepper motors are ideal for fine positioning without feedback, especially in precise, small-volume dosing tasks.

- Servomotors offer a high level of control in dynamic dosing applications thanks to feedback systems.

- Three-phase motors are suitable for robust industrial applications, especially when dosing larger or more viscous quantities.

Pneumatische Antriebe

use compressed air to generate movement. These actuators are particularly robust in dirty or hazardous environments and are safe to use in potentially explosive atmospheres. They offer simplicity and reliability as they have few moving parts and are easy to maintain. Their safety with flammable materials results from the absence of sparks during operation. Although less expensive to purchase than complex electrical systems, they offer less precision in comparison. Their fast and powerful movement makes them ideal for applications that require less finesse but high reaction speed and robustness.

Hydraulische Antriebe

use fluids under high pressure to generate large forces, making them ideal for heavy loads and high-pressure applications. They are widely used in heavy industry where large quantities of materials need to be moved or metered. These actuators are characterized by their ability to handle significant loads, which makes them particularly suitable for demanding industrial tasks. However, hydraulic systems require more complex maintenance and consume more energy compared to other drive types. Despite these disadvantages, they offer a reliable and effective solution for many industrial challenges where maximum force application is required.

What are frequency inverters and how do they work?

Frequency inverters are electronic devices that control the speed of an electric motor by varying the frequency of the current supplied to the motor. They convert the incoming alternating current into direct current and generate an output alternating current of variable frequency.

By changing this frequency, frequency inverters can precisely control the speed of motors. This ability to precisely regulate motor power makes them particularly valuable in applications where process optimization and energy efficiency are critical.

Advantages of frequency inverters in drive technology

Adjusting the motor speed with frequency inverters

Adjusting the motor speed is one of the main functions of frequency inverters. By changing the frequency of the current supplied to the motor, users can flexibly control the speed of the motor. This is particularly beneficial in production environments where different materials or processing steps require different speeds.

Integration of frequency inverters for optimum feeding results

Challenges in the implementation of frequency inverters

The introduction of frequency inverters into existing systems can pose technical and organizational challenges. Technically, the installation requires precise coordination between the frequency inverter and the motor characteristics in order to avoid efficiency losses and possible damage. Organizationally, training staff to use this technology can be a challenge, as a deep understanding of how the devices work and how to program them is required. In addition, existing processes often need to be adapted or reconfigured in order to take full advantage of precise speed control.

Synchronization of frequency inverter and control technology

The synchronization of frequency inverters with the control technology is crucial for efficient and precise process control. Good synchronization enables the frequency inverter to respond smoothly to control signals and precisely adapt the motor power to the requirements of the process. This requires careful programming and often the integration of feedback systems that provide real-time data on motor performance and process parameters. This data helps to fine-tune the frequency inverter settings to achieve optimum tuning and therefore improved product quality and process efficiency.

Factors for selecting a frequency inverter for dosing devices

When selecting a frequency inverter for dosing devices, various key factors must be taken into account:

- Motor power: The power requirements of the motor must exactly match the specifications of the frequency inverter.

- Operating conditions: The type of material being dispensed and the required precision and repeatability of dispensing are crucial.

- Environmental conditions: The devices must be suitable for the specific environmental conditions, including temperature, humidity and possible exposure to chemicals or dust.

- Operational safety and efficiency: The selection must maximize both operational safety and energy efficiency in order to minimize operating costs.

These factors help to select a frequency inverter that is optimally matched to the specific requirements and conditions.

Individual consulting by DEMIC Datentechnik GmbH

DEMIC Datentechnik GmbH offers customized consulting services to help companies select the optimal frequency inverter for their specific dosing applications. DEMIC's experts take into account all relevant factors, such as the technical specifications of the dosing equipment, the chemical properties of the materials to be dosed and the ambient conditions. Through this customized advice, DEMIC ensures that customers receive a frequency inverter that is not only technically compatible, but also offers the highest possible efficiency and reliability in their specific applications.

Best practices for setting up and maintaining frequency inverters

Installing frequency inverters - What you should think about

There are several important points to consider when installing frequency inverters:

- Choice of location: Choose a location with sufficient ventilation and protection from extreme temperatures and humidity.

- Electrical safety: Ensure that all electrical connections are correct and safe to minimize electrical safety risks.

- Compatibility: Check the compatibility of the frequency inverter with the motors and other system components to be controlled.

- Commissioning: After installation, carry out a thorough commissioning to ensure that all systems are working correctly and are set efficiently.

These preparations help to ensure that the frequency inverter functions optimally and that potential problems are detected at an early stage.

Maintenance of frequency inverters to extend their service life

Regular maintenance is essential to extend the service life of frequency inverters and maintain their performance:

- Regular inspections: Regularly check all electrical and mechanical components for wear or damage.

- Software updates: Carry out software updates to ensure that the frequency inverter works with the latest technology and offers optimum performance.

- Cleaning: Keep the frequency inverter and its surroundings clean to avoid overheating and accumulation of dust that could affect performance.

- Documentation: Keep detailed records of all maintenance activities and any problems to facilitate future maintenance and ensure continued performance.

These maintenance practices help to minimize failures and ensure the reliability of the frequency inverter over its entire service life.

Importance of the control system for precise dosing

Control technology plays a central role in dosing technology by ensuring the precision and reliability of the processes. It makes it possible to precisely control the quantity, speed and timing of the materials supplied. This is particularly important in industries such as pharmaceuticals and chemicals, where precise dosing is crucial for product quality and safety. Advanced control mechanisms allow dispensers to deliver consistent results even under varying environmental conditions and material properties.

Manual controls

Manual controls require direct human intervention to operate the dosing devices. They are easy to use and often inexpensive to purchase. This type of control is suitable for smaller or less complex operations where simple adjustments are sufficient and no high demands are placed on precision.

Programmable logic controllers (PLCs)

PLCs are robust and reliable electronic devices that have been specially developed to perform a wide range of industrial control and automation tasks. They are programmable, which means that they can be flexibly adapted to different operating conditions and requirements. PLCs are ideal for complex dosing systems that require fast processing of signals and precise control.

Computer-based control systems

Computer-based control systems offer the highest flexibility and precision for dosing technology. They utilize advanced software that enables complex algorithms and process control. These systems can be easily adapted to changing parameters and offer extensive diagnostic and monitoring functions, making them particularly suitable for highly automated and precision-critical applications.

Why is tuning essential?

Challenges with synchronization

Best practices for optimal coordination

Define requirements

Before selecting the right drive technology for dispensing equipment, it is crucial to clearly define the specific requirements of the dispensing process. This includes understanding the type of material to be dispensed, the required precision, the throughput rate and environmental conditions such as temperature or potential explosion risk. Operating costs and maintenance requirements must also be taken into account. A precise definition of these parameters helps to select a drive technology that ensures optimum performance and efficiency in the intended application.

Selection criteria for dosing device drives

The selection of the right drive for dosing devices is based on several criteria. The most important of these include the type of drive (electric, pneumatic, hydraulic), energy efficiency, controllability, scalability and the ability to integrate into existing systems. Operational safety also plays a key role, especially in regulated industries such as pharmaceuticals and chemicals. The ability to dispense precisely and reproducibly and to adapt quickly to changing production conditions are also decisive factors in the selection process.

Why expert advice is important

Choosing the right drive technology can be complex, especially in specialized or high-tech applications. Expert advice is therefore essential to avoid costly mistakes and safeguard investments. Experts can not only help to precisely define the technical requirements, but also suggest the latest technologies and solutions that are specifically tailored to the needs of the production process in question. Through their experience and expertise, they help companies maximize operational efficiency and ensure compliance with industry standards and safety regulations.

Regular maintenance intervals

Determining regular maintenance intervals is crucial for the longevity and efficiency of the drive technology in dosing devices. It is advisable to draw up maintenance schedules based on the manufacturer's recommendations and also take into account the specific operating conditions. Regular maintenance should include inspections, cleaning, lubrication and the inspection and replacement of wearing parts. Monitoring system performance and any software updates are also important. These measures help to increase operational reliability, maintain equipment performance and avoid unexpected breakdowns. A well-planned maintenance cycle makes a significant contribution to reducing the total cost of ownership and increasing productivity.

Preventive maintenance strategies

Preventive maintenance plays a crucial role in minimizing downtime and extending the service life of drive systems. This strategy is based on regular inspection and maintenance of equipment to identify and rectify problems before they lead to serious failures. Modern monitoring technologies, such as vibration sensors and thermography, are used to detect signs of wear or malfunctions at an early stage. A proactive approach to maintenance enables planned maintenance to be carried out, which is less invasive and more cost-effective than reactive repairs following a breakdown. Effective preventive maintenance plans take into account the operating conditions of the drives and are geared towards optimum performance and a long service life of the drive technology.

Innovative developments

The future of drive technology in dosing devices will be strongly influenced by innovations that increase efficiency, precision and adaptability. Notable developments include the use of smart motors, which are equipped with integrated sensors to record operating data in real time and make adjustments independently. These intelligent drive systems enable more precise control and diagnostics, which simplifies maintenance and increases operational safety. Furthermore, the integration of artificial intelligence to predict maintenance needs and optimize dosing processes will play an increasingly important role.

Trends in drive and control technology

Current trends in drive and control technology for dosing devices show a clear movement towards further automation and digitalization. The networking of drive systems via the Internet of Things (IoT) enables improved data collection and analysis, which is used to make more precise control decisions. In addition, the development of energy-saving and environmentally friendly technologies is being driven forward in order to support sustainability goals. These trends point to a future in which drive and control systems will become increasingly complex, but also more efficient, adaptable and user-friendly.

Would you like to find out more about drive technology for dosing devices?

We look forward to advising you:

PHONE: +49 2247 918 90

E-MAIL: kontakt(at)demic-datentechnik.de